Construction lags other industries where productivity is concerned, thanks in part to its notoriously slow uptake of new technology. Using new digital tools, and doing so more often, could boost productivity by 50% to 60%, generating $1.6 trillion in value, according to McKinsey research.

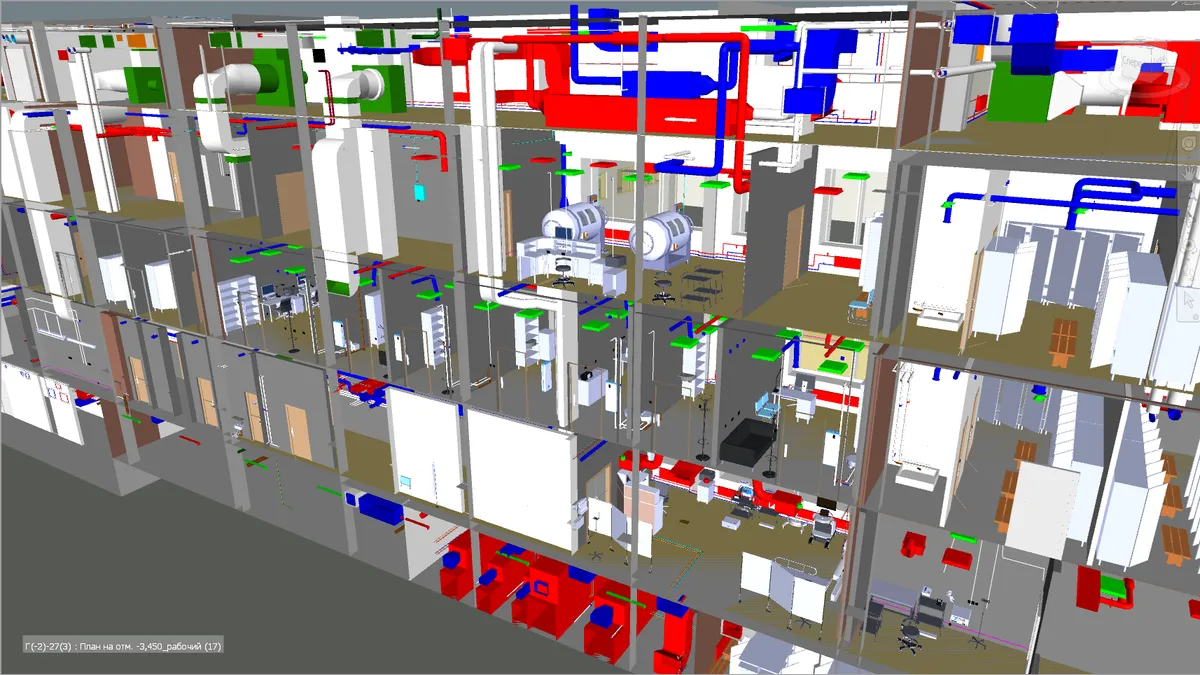

But that forecast doesn't tell the entire story. Some contractors have already embraced new technology at various levels — for example, through digitization, BIM, laser scanning and drones. As a result, they have been able to contribute to the design and construction process earlier and at a more substantive level than they could before.

"[Technology] makes our processes more efficient, and it allows us to give our client a better product," said Sam Arabia, director of engineering and BIM services at Torcon, a construction management and general construction firm based in Red Bank, NJ.

Getting involved early

Torcon, which provides BIM models as a matter of course, has an arsenal of technology at its disposal. It uses those tools and its team of trained engineers when performing as a construction manager at risk, evaluating a design's constructability as soon as the contract is executed.

"We contact the design team and ask for a Revit model and send them our VDC (virtual design and construction) plan and try to set up a collaborative meeting right away," Arabia said. That is meant to set the tone for the relationship as one of openness and transparency.

Owners are also becoming more educated as to the potential of BIM and other high-tech tools, said Sarah Hodges, director of Autodesk's construction business line. The unit turns out such industry BIM staples as Revit and Navisworks, through which users can combine and review 3-D models. Owners are increasingly challenging contractors on design options, she said, so contractors need to be familiar with the latest digital tools.

"[Technology] makes our processes more efficient, and it allows us to give our client a better product."

Sam Arabia

Director of engineering and BIM services, Torcon

"BIM is facilitating this collaborative environment where architects, contractors and engineers can work together and model a project before it is even bid on and won," she said.

Specialty contracting firm GEM, based in Walbridge, OH, and part of the Rudolph Libbe Group, also shoots for early involvement. "Collaboration comes about in many ways, but it always starts immediately," said A.J. King, mechanical designer and VDC team leader for GEM. Because GEM is a specialty contractor, first contact for a project typically happens with a general contractor. During these initial communications, GEM lets the general contractor know how they can aid in the design process, be it through laser scanning or BIM integration, King said.

New opportunities

Geoff Camp, a Florida-based regional VDC manager at Suffolk Construction, has seen similar opportunities. "The proliferation of these kinds of tools has allowed us to partner with and work with designers in more meaningful ways," he said.

Those ways range from the functional to the complex, and include new construction and renovations.

GEM's specialties include electrical and mechanical renovations and upgrades to industrial facilities. The company uses laser scanners to obtain accurate dimensions.

Torcon also uses laser scanning when preparing for commercial building rehabilitation and remodeling work.

The building boom of the 1980s and '90s created a steady stream of current rehab projects, Arabia said, but many of those buildings lack as-built drawings and specifications. "It's impossible to know what's going on behind the walls and above the ceiling," he said.

This is where Torcon's laser scanning and drones come in handy.

Torcon can fly a drone over a site and overlay images onto a topographical map. That process takes a day versus the former surveying process, which depending on the job could take days or months. Inside the building, the company uses its laser scanner to produce a point cloud, which replicates as-built conditions to one-eighth of an inch. They then compare those to the design team's model. "It validates their assumptions before they become challenges in the field," Arabia said.

"BIM is facilitating this collaborative environment where architects, contractors and engineers can work together and model a project before it is even bid on and won."

Sarah Hodges

Construction business line director, Autodesk

Laser scanning is particularly useful in an environment like a hospital, where the technology allows designers and contractors to work around existing critical systems while they remain operational.

The design teams Torcon works with now ask for a laser scan. "[The scanner] is used all the time," Arabia said. "It's invaluable. People count on it."

Staffing Torcon’s BIM division has been challenging, however. "Over the last two years, one of the hardest positions to fill has been that of BIM engineer," Arabia said. Each engineer has to know not only the software but also how a building comes together. A typical Torcon BIM engineer handles an average of three or four projects at a time, though some jobs are big enough to be an engineer's sole focus.

Staying in your lane

Hodgson said some design and construction teams have joined forces under one roof to "bridge the gap" between the creative and the practical, as well as to capture the financial benefits that come with ownership of a bigger chunk of the project. For the most part, however, there is a line when it comes to taking on work that has traditionally been the territory of the architect or other professional designers, and contractors are careful not to cross it.

For example, King said GEM would not design an entirely new boiler system, as that element of a project is typically managed by architects and engineers.

"We recognize the critical, important role of designers," Suffolk's Camp said. "I don't see us ever taking on that role. These tools let the designer focus on things they do best and let us take on more of the details." Allowing designers to focus more on creativity and vision, he said, leads to a "rich back and forth" that is important on a large team.

"Our primary goal is to be as collaborative as possible with the design team," Arabia said. "It's how you approach it and how you communicate."