Melo is vice president and general manager, Global RFID, Avery Dennison.

A technology used to track inventories of sweaters and jeans and ensure the on-time arrival of luggage on commercial airliners could hold the key to tackling food waste, collectively saving food retailers billions of dollars and helping them play a critical role in addressing global food security and hunger.

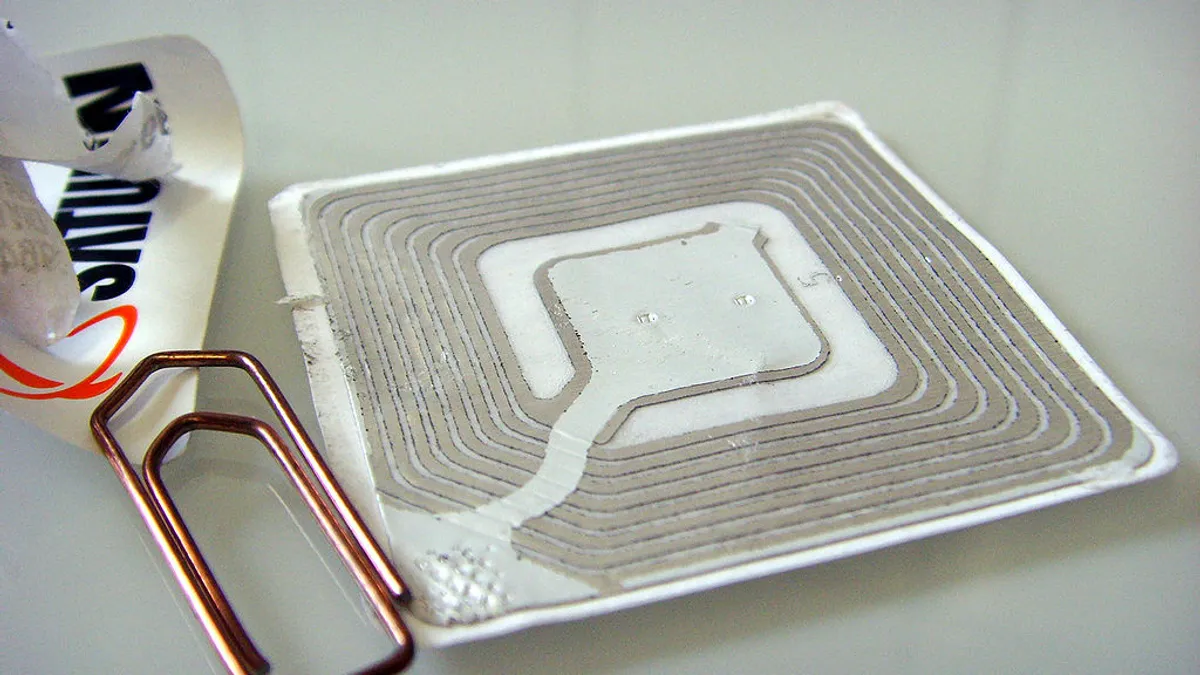

Radio frequency identification (RFID) tags have been used by apparel and consumer product retailers for years, improving efficiency and quickly identifying stock in warehouses and on store shelves.

Bill Hardgrave, dean at Auburn University’s Harbert College of Business and an RFID expert, says the business benefits of this technology have “about 50% of leading apparel brands, department stores and mass merchants around the world assessing, testing, or adopting RFID.”

RFID tag systems contain chips that store data about the product to which they are attached. They have massive advantages over inventory systems that rely on traditional barcodes because RFID chips have a unique identity, can store extensive information, can be read at greater distances, work quickly and don’t require a direct line of sight for scanning.

In 2016, a major U.S. airline replaced barcode hand scanning used since the early 1990s with RFID technology to cut down on lost luggage. The initial deployment of the technology over the course of a year tracked bags at a 99.9% success rate, compared to a rate of only 85 percent for the barcode system. This high level of accuracy can drastically reduce baggage mishandling, saving millions of dollars and lots of time.

The technology, proven and successful in the retail and airline industries, can have a similar impact in the food industry, where food waste is a costly and complex problem.

The United Nations Food and Agriculture Organization reports that “roughly one-third of the food produced in the world for human consumption every year — approximately 1.3 billion tonnes — gets lost or wasted.” That loss and waste, the U.N. agency says, amounts to a massive waste of resources each year – “roughly $680 billion in industrialized countries and $310 billion in developing countries.”

It’s no surprise that food retailers are constantly challenged by the need to balance availability of products with stocking that can lead to waste. This happens when, for example, items are overstocked for promotions; there are over-deliveries to a store; or stocks aren’t rotated and older items get buried on shelves behind newer ones.

The time and labor costs to manage a store’s stock is significant. Grocery stores operate on razor-thin margins, so any opportunity to improve efficiencies in food delivery and stock management is worth considering. That’s exactly why my team at Avery Dennison has begun piloting RFID solutions with global food retailers.

Last summer, we completed a pilot with a leading U.K.-based food retailer, which included the deployment of the first food-friendly intelligent label. These labels can store or capture information via sensors and wirelessly transmit data, which can be read in refrigerated environments and other settings specific to the food industry.

The results are encouraging. Preliminary analysis of the three-month pilot program points to a potential 20% reduction in food waste, and potential to reduce food stock management costs by about 50%. We are also seeing dramatic improvement in inventory accuracy — more than 99% — in food distribution across the supply chain.

The issue of food waste and the financial hit it can cause the food industry are becoming serious concerns on Wall Street. The Natural Resources Defense Council, along with Trillium Asset Management, which specializes in sustainable and responsible investing, recently called on investors to encourage companies to “step up their game and move toward greater innovation, accountability and transparency about food wasted in their operations and supply chains.”

RFID intelligent labels can help the industry step up its performance game and more. They can help get unpurchased perishable items to food banks more quickly to feed hungry families, prevent food from unnecessarily going into landfills and harming the environment . They can aid in the overall transformation of food systems to promote food security.

A 2016 report from the Chicago Council on Global Affairs notes the host of pressures on today’s food systems. They include everything from exploding global populations and the largest global refugee migration since World War II to climate-change related weather volatility, which affects crops and food production.

Based on life cycle assessment findings from the Journal of Food Engineering, identifying more sustainable food production practices — like technological advancements — is critical.

With deployment of intelligent labels, food waste at the grocery store doesn’t need to be a contributing factor to stressed food systems or strained profit margins.